Heat Treatment

- Jan 2, 2017

- 2 min read

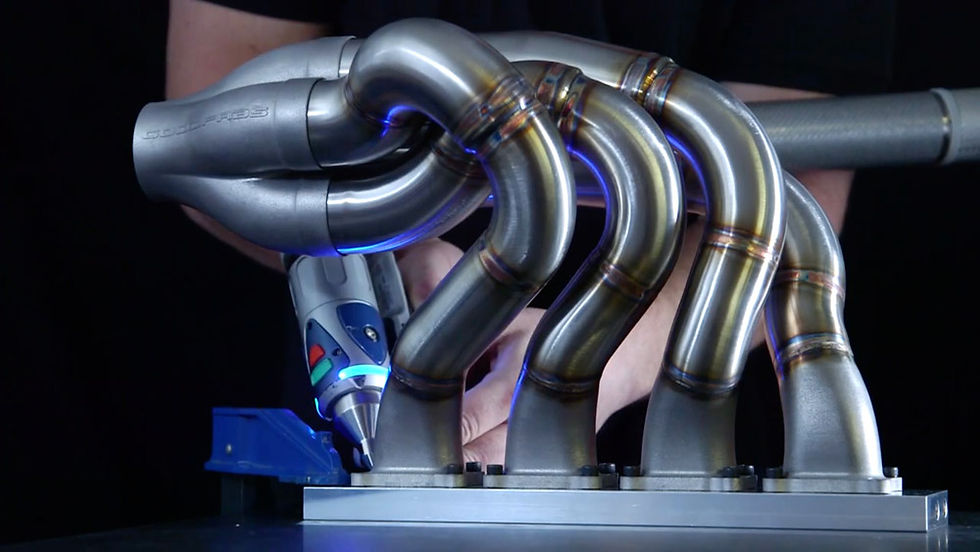

The welding process when fabricating exhaust parts induces some residual tensile stresses in the joints. These tensile stresses act to stretch or pull apart the material surface which might initiate a crack when there are enough load cycles. To improve the life of these welded metal fabrications, the residual stress levels in the materials (this can be stainless steel, inconel) need to be modified.

This can be done using either a shot peening process or a heat treatment.

WHAT IS HEAT TREATMENT?

Heat treatment is a process where the metals (inconel, stainless steel, aluminium, etc.) are heated and cooled in a fully controlled environment to change their microstructure and to bring these metals closer to its equilibrium state, or bring out more of the physical and mechanical characteristics of this material.

WHY ARE STRESSES PUT IN THE MATERIAL?

The residual tensile stress from welding inconel, stainless steel, aluminium, etc. is created because the weld consumable is often applied in a liquid state.

The welding process consists of heating up the metal, then the weld is applied in its hottest, most expanded state. When the much cooler consumable material is bonded to the base material, the weld tends to cool rapidly and will attempt to shrink from the drop in temperature. Because the base material is usually much stronger and not in a molten state, this cannot shrink, leaving the material remaining in a highly stressed “tensioned” state.

This zone is usually just next to the weld joint, which explains why a crack usually appears “right next to the weld”.

TYPICAL HEAT TREATMENT BEHAVIOUR

The graph below shows a typical situation of a welded metal component before and after heat treatment.

As can be seen from the graph, the residual stresses in the welded metal such as inconel, stainless steel, etc. are positive, which puts the outer surface layer in a tensional state.

When the metal is heat treated in a controlled environment to stress relieve the residual stresses, we can see that the metal reaches an equilibrium state and the residual stresses are close to zero.

This graph does not refer to any specific material and is purely for illustration purposes.

COMBINING HEAT TREATMENT WITH SHOT PEENING

Heat treating an exhaust system can enhance its properties. Annealing can soften a part and make it more flexible and less prone to cracking, while other treatments may make it stronger.

Heat treatment is typically carried out overnight although some process may take significantly longer.

When combined with shot peening , which sometimes follows heat treatment on same day, the material properties could be enhanced even more, as illustrated in the above graph.