Oxidation of a Nickel Superalloy in Formula 1

- Good Fabrications Ltd

- Sep 7, 2017

- 1 min read

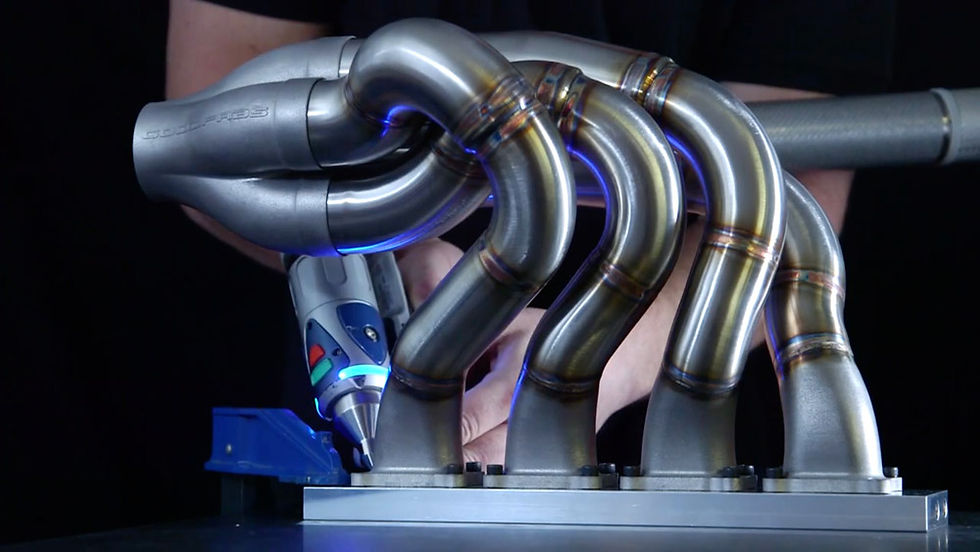

In collaboration with the Department of Materials Science and Metallurgy, University of Cambridge, Department of Earth Sciences, University of Oxford, the Department of Materials, University of Oxford, Rolls Royce and Oak Ridge National Laboratory, Materials Science and Technology Division, Good Fabrications was able to investigate the oxidation response and microstructural evolution of an Inconel 625 alloy exhaust manifold exposed to a Formula 1 racing environment.

This has been examined using a range of advanced electron microscopy-based techniques, atom probe tomography and high-sensitivity laser ablation mass spectrometry. The dynamic, corrosive gas conditions result in accelerated oxidation, with the inner exhaust surface also heavily contaminated by multiple species including Zn, P, K and Na. Nb carbides and Ti nitrides identified in stock control samples evolve into mixed (Ti, Nb)N species during exposure, decorated by smaller Mo, Si-rich precipitates. The exposed alloy component therefore reveals unique surface and subsurface features following in-service use.