Titanium alloys

- Good Fabrications Ltd

- Jan 15, 2017

- 1 min read

Titanium Grade 1 is also known as commercially pure titanium and is one of the softest titanium grades with high formability and excellent weldability.

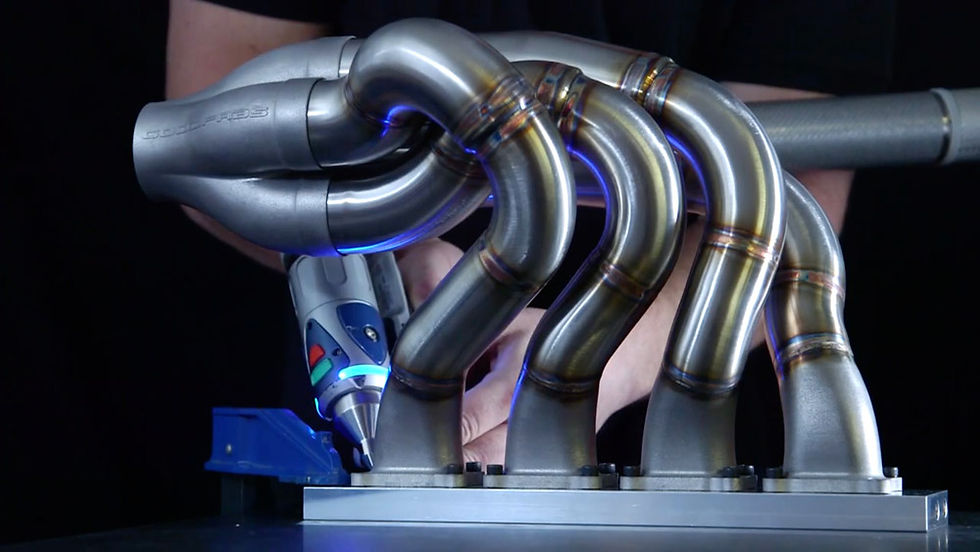

Because it is lightweight, with good corrosion resistance, this material is often used in exhausts on motorbikes and other applications where bends and shapes are required.

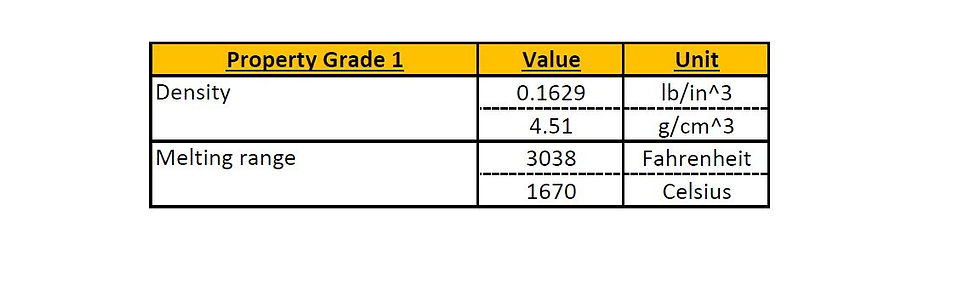

Physical Properties/ Mechanical Properties

Titanium cannot be hardened by heat treatment. However through hot forming, the springback will reduce and the overall ductility of the material will increase.

It is possible to cold work titanium - its behavior is similar to that of austenitic stainless steels.

Composition

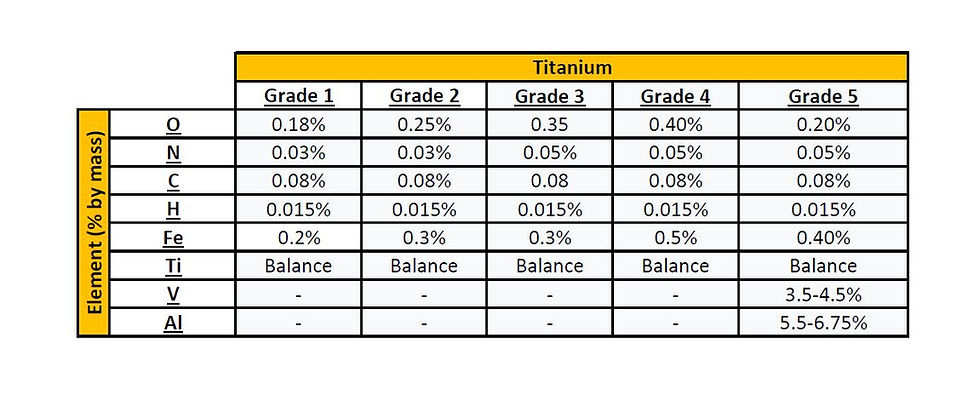

Titanium comes in different categories:

commercially pure titanium which is unalloyed

alloyed titanium

Each has their strengths and weaknesses.

The table below only shows values for the commercially pure titanium where grade 1 is the softest titanium with the highest ductility but the lowest strength through to grade 5 which offers the highest strength but only has a moderate formability.

Machining and Welding

Titanium is not a nightmare to machine, as some might say.

Many machinists compare the behavior of this material to stainless steel 316 where a high coolant flow is needed together with a slow speed and high feed rate.

Titanium has good weldability properties because of its nature as a single-phase material.

Consequently, the mechanical properties of the weld are equal to or even better than the parent material and no post-welding heat treatments are needed.

Titanium is known to turn blue when this is heated. This is because it is a reactive metal where it reacts to heat by creating an oxide layer of a blue color.