The challenge of designing a winning NASCAR exhaust system

- May 9, 2017

- 2 min read

In many racing series the regulations are constantly changing. This is also the case in the high performance racing series like NASCAR.

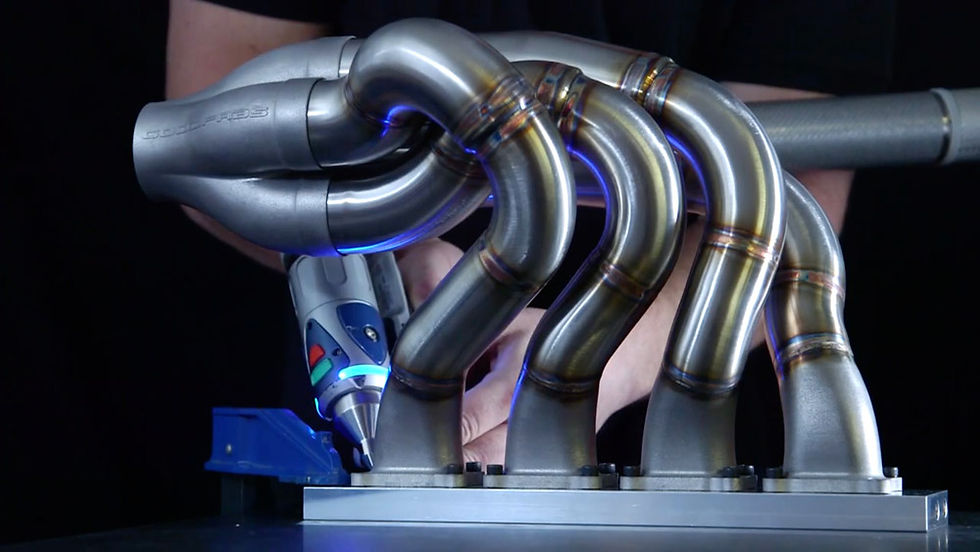

The NASCAR Sprint Cup regulations for example make the routing of the exhaust system and its assembly quite a challenge, especially where a reduced weight of the exhaust system is needed while maintaining reliability.

The regulations are quite open for development of the engine itself which often causes that the development of the exhaust system is pushed to the back of the queue. However the exhaust is one of the areas where a lot of performance is either gained or lost.

The main goal for the perfect exhaust system is to reduce the pressure losses throughout the system to a minimum. Because of the ovalised sections in these NASCAR systems are constrained in the regulations this can cause a reduction of power if this is not designed properly.

Some racing series have used these oval shapes on purpose with intentionally harming the performance of the engine to gain a performance somewhere else. This was the case in 2012 where we at the forefront of developing the exhaust for blown diffusers in Formula 1.

When designing these ovalised shapes (and taking into account the regulations for cross sectional areas) the actual hydraulic diameter needs to be taken into account. This could increase the pressure losses considerably as the ovalised section can be relatively long.

In most racing series the exhausts start out as a tubular (round) shape and maintain this shape up to the exit of the system. Because of the regulations in NASCAR this round shape changes to the ovalised regulated section at some point. To do this often a tapering transition piece is made by press forming the materials into the correct shapes.

With every this change in geometry, the dynamics of the exhaust gas change (see our article about How exhaust gas dynamics work).

Therfore these transition sections need to be carefully designed considering the crossectional area of every section throughout the system geometry changed to maximise the performance of the system.

When the area change is too drastic there is a danger of having a flow separation on the walls causing turbulent areas and a very large pressure loss in this transitional section.

At Goodfabs we have been serving NASCAR for decades now and have been closely creating development exhaust systems on the car and on the dyno to maximise the performance within the engine regulations.